Energy Observer tests a new wind turbine thruster

Although it’s an inexhaustible resource at sea, wind is still difficult to exploit for large scale maritime transport. In its role as an experimental vessel, Energy Observer has set its mission to test all of the available and promising solutions. During its first navigation seasons, Energy Observer experimented with two vertical-axis wind turbines for production, and a traction wing to reduce energy consumption.

In 2019, the vessel will test a completely new system combining the advantages of the former system with a new one: a wind propeller. The Oceanwings® are going to reduce the vessel’s energy consumption, accelerate its speed, and above all, enable it to produce energy and hydrogen while navigating.

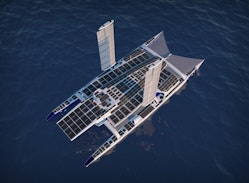

Energy Observer 3D image with Oceanwings®

12-meter wingspan

The Oceanwings® are the largest to be tested to date. They are the fruit of a concept patented by VPLP Design co-developed in partnership with CNIM, where they are assembled. Energy Observer will, thus, enable a unique experience feedback for the future of maritime transport. With a surface of 31.5 m², each wing is self-supporting and has a rotation capacity of 360°.VPLP Design gets its inspiration and experience from the rigid wings of the America’s Cup whose aerodynamic efficiency is superior to traditional sails. One fundamental reason has, however, limited their development: precisely their rigidity. Up to now, they have lacked the ability to reduce the surface area, in other words their reefing and dumping capacity, as in a classic rigging.

Operation of the Oceanwings

With Oceanwings®, VPLP Design hopes to offer a simple solution to overcome this obstacle and generalize the use of rigid wings.

“We want to propose a wind-powered propulsion system that is sure, simple, and can be automated. We’ve therefore developed a concept of sustainable and reefable rigging, based on the aerodynamics of the multi-element profiles of the Cup.”

Thanks to Ademe, a complete functional prototype with a wingspan of 8 m permitted validation of the wing feasibility, making the systems more reliable, and to complete the navigation surveys on the performance prediction models (VVP) developed internally.

In fact, it was while navigating on the prototype with Marc Van Peteghem, during Energy Observer’s Odyssey for the Future, that this technology won Victorien Erussard over.

For the first stage they’ll be covered with Hydranet, a resistant fabric that can painted or varnished.

A performance multiplier for Energy Observer’s energy mix

On board Energy Observer, the Oceanwings® won’t only serve as part of the rigging, they will actually increase the vessel’s energy efficiency. Their installation on the vessel’s two floaters will in fact allow it to:

-Increase the speed, by complementing the electric motors

-Reduce energy consumption when they are used to compensate the electric motors

-Increase energy production during navigation by producing hydrokinetic energy (reversing the electronic motors into hydrogeneraters)

-Produce hydrogen during navigation by the electrolysis of water

This is one of the main breakthroughs for Energy Observer. Up until now, hydrogen production was only possible during stopovers, but the installation of Oceanwings® will make hydrogen production possible while the vessel is navigating. It will only be for 1 to 2 hours a day in the beginning, but introducing hydro-generation by inverting the electric motors is an indispensable power supplement in Northern Europe where the sunlight conditions are not as favorable.

Up to a 42% decrease in energy consumption for global maritime transportation

The installation of Oceanwings® on board Energy Observer is the first step to reducing the environmental impact of maritime transportation around the world. According to simulations carried out on a large range of boats, the results are extremely promising: from 18% to 42% less energy is required. An important statistic when one recognises that 90% of global commerce is transported at sea. Maritime transportation is also responsible for large quantities of air pollution, emitting into the atmosphere pollutants such as fine particles, nitrogen oxide (NOx), and sulfur oxide (SOx).

Energy Observer 3D image with Oceanwings®

“Au-delà de la technologie pure, que nous avons hâte de tester à bord tant le système a l’air performant et automatisé, je crois profondément que ces ailes peuvent constituer une véritable rupture technologique dans la réduction des dépenses énergétiques des navires de commerce. Associées à l’hydrogène, c’est le combo gagnant pour un transport maritime propre”

A solution for industrialization

The Oceanwings® approach is based on a logic of cost-efficiency and eco-responsible design. If wind-powered propulsion allows a double-digit reduction in fuel consumption, it would not need a dedicated crew member; automation of the rigging is unavoidable. Industrialization, considered from the design stage, allow the proposal of this technology at a price comparable to a high-performance rigging. For professionals, it will quickly pay for itself.