Bioethanol: the Brazilian success story

If there’s one thing that is typical of Brazil ‘s energy landscape, it’s ethanol. Throughout our journey, our production team was able to travel on ethanol in the region of São Paulo, traversing sugarcane fields and passing by ethanol mills. But what exactly is ethanol, and how does it emerge as a promising alternative energy source? Our energy expert, Beatrice Cordiano tells us more about this Brazilian success story!

Beatrice Cordiano in Brazil

Ethanol, the most popular alcohol, and the only one deemed safe for human consumption, is essentially ethyl alcohol: the same alcohol found in drinks and the familiar pink liquid our grandmothers used for household cleaning. In Brazil, ethanol goes beyond these conventional uses and transforms into a fuel, or better a biofuel, a substance derived from plant or animal biomass which industries look at as a compelling alternative energy capable of reducing emissions. Whether as fuel for combustion processes, contribution to cogeneration systems, power source for fuel cells, or a crucial feedstock for chemicals, bioethanol boasts a versatile range of applications but the broadest one, here, is as a valid and more sustainable substitute for traditional petrol in engines.

From crisis to opportunity

In Brazil, the ethanol industry has always been intricately linked with the sugar industry. The country has long held the title of the world’s largest producer of sugar, annually exporting about 30 million tons of sugar, surpassing the export volumes of its closest rival, Thailand, by more than fourfold. This business is obtained through the extraction and the evaporation of cane juice, a process that has long been a cornerstone of Brazil’s economy. The story of Brazil’s ethanol production can be traced back to 1933, when the government, faced with the challenge of sugarcane overproduction, took proactive measures to revive this industry. In a strategic move, incentives were provided to use surplus sugarcane for ethanol production.

Sugarcane plant in Brazil

40 years later, the global landscape witnessed a seismic shift when the OAPEC (Organization of Arab Petroleum Exporting Countries) imposed an embargo on oil exports, triggering a huge shock in the global oil prices and the onset of the First Oil Crisis. This had a devastating impact on economies around the world, including Brazil, which was back then reliant on imported oil, and which saw an opportunity amidst the crisis. In 1975, Brazil introduced the Proálcool plan, an initiative aiming to reduce the country’s reliance on foreign fossil fuels by blending petrol with ethanol, investing heavily in research and development, expanding sugarcane cultivation, and increasing the capacity of ethanol plants. The country's efforts paid off and by the time the second oil crisis hit in 1979, Brazil was already well on its way to becoming a world leader in ethanol production. Today, with oil prices that keep on increasing, the country’s ethanol industry is more evident than ever.

From sugar to alcohol

Ethanol is produced by the extraction of sugars from agricultural crops and in Brazil, where green sugarcane plantations cover the land as far as the eye can see, sugarcane has been the primary feedstock for this fuel for over four decades. The process of transforming sugarcane into ethanol involves a series of meticulously controlled steps, combining ancient techniques and cutting-edge technologies. Mechanized harvesters efficiently gather mature stalks, transporting them to processing mills, where they are cleaned and cut. Cane stalks are then crushed to extract a sugar-rich cane juice which is fermented thanks to a yeast that breaks down sugars into alcohol and carbon dioxide. That is the same process used to produce beer or wine.

It is no wonder that the quality standards for using this type of fuel in car engines are stringent, and to meet them, the fermented solution containing ethanol and impurities needs to undergo distillation. Here it is heated, vaporized, and recondensed to remove as much water as possible, resulting in concentrated ethanol which can be used in cars, pure or blended with gasoline.

A blend of choices

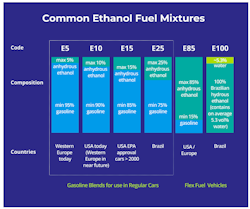

Ethanol can be added to petrol for it to be burned more cleanly and all over the world, it is possible to find different ethanol blends, each tailored to specific needs and preferences. The most widely available mixtures are E5 and E10, incorporating up to 5% and 10% ethanol respectively, and are compatible with most gasoline-powered vehicles, which is not the case for higher percentages of ethanol. In fact, when increasing the amount of ethanol in the mixture, some compatibility issues can arise with conventional engines and modifications are required.

In Brazil pure gasoline is no longer sold, and a mandatory ethanol blend requirement of 27% (soon to be 30%) is present. This forced the adoption of flex fuel vehicles, cars that can switch between any gasoline-ethanol blend, from 100% gasoline to 100% ethanol.

Common Ethanol Fuel Mixtures

It is all about the carbon cycle

Ethanol’s chemical formula is CH3CH2OH: six atoms of hydrogen, one atom of oxygen and two atoms of carbon, which, during combustion, are converted into water and CO2. Ethanol combustion is clearly not zero emissions. However, when considering the total cycle from the plant’s growth to the engine’s exhaust, this fuel reduces greenhouse gases emissions by 50 to 70% compared to conventional fossil fuels. This environmental performance lies in the closed-loop nature of bioethanol production: plants, during photosynthesis, capture carbon dioxide from the atmosphere, which is then released back into the ait during fuel combustion. That ensures that the carbon cycle remains balanced, earning biofuels the designation of carbon neutral fuels.

The problem arises when the plantations are not managed sustainably, clearing lands and causing deforestation. But in Brazil, where sugarcane plantations are concentrated in the São Paulo region far away from the Amazon Forest and cover only 1,2% of the whole territory and 4% of agricultural lands, regulations on sugarcane plantations are strict and abundant.

Sugarcane plant in Brazil

New outlooks for the ethanol market

Brazil ’s success with biofuels doesn’t go unnoticed: the country currently stands as the world’s second largest ethanol producer, just behind the United States, and has recently positioned as a leader in 2nd generation ethanol production, inaugurating the one and only commercial production site worldwide. This type of ethanol, also known as cellulosic ethanol, derives from non-food biomass like sugarcane bagasse, a byproduct of traditional ethanol and sugar manufacturing, and not only can mitigate land-use conflicts with food crops, but can also- increase the overall biofuel sustainability and enhance productivity yielding 50% more fuel for the same surface.

Beatrice Cordiano in Brazil

Aviation - we all know that - is a hard-to-abate sector accounting for around 2% of global emissions, and even if several promising technologies like batteries, hydrogen and fuel cells are under development, their impact on reducing aviation emissions may be limited. As a result, sustainable aviation fuels (SAFs) have emerged as the most technically viable option to decarbonise this sector. These drop-in fuels can directly replace jet fuel, offering GHG reductions of up to 70% depending on the feedstock. Ethanol can be transformed into hydrocarbons through the alcohol-to-Jet process and Brazil, with its established ethanol industry and its readily available sugarcane bagasse, stands at the forefront of SAF production. Currently fine-tuning the technology, it has the potential to scale up production to 6000 barrels per day by 2030 and 700 000 by 2050 (namely 35% of the expected global production capacity by then) , which – with the proposed airlines’ emission reduction targets and SAF blending mandates – will set Brazil as a crucial supplier to the global market.