A feedback from 6 years of onboard photovoltaic experimentation

Solar energy is the primary source of energy for our laboratory vessel. This energy is converted into electricity, then stored in our battery system or in the form of hydrogen for long-term storage. On board, the photovoltaic system is severely tested, particularly in the more tropical latitudes where our catamaran have remained during two years, from mid-2021 to mid-2023. Our engineers are constantly working on maintaining and improving this essential component of our energy mix. Explanations with Luc Bourserie, onboard systems engineer.

The principle of a floating laboratory

Since the beginning of our Odyssey, solar power has been our boat's primary source of energy. Even when the sun is gone, it is mainly solar energy that has been converted into electricity, then stored in our batteries or in the form of hydrogen, which is used to power the systems, for life on board or propulsion to complement wind power. Energy Observer's technical teams have always sought to optimize the boat's photovoltaic system, and are now redoubling their efforts when facing rough weather.

Energy Observer is a floating laboratory! Our vessel is primarily used to test and improve cutting-edge technologies in extreme conditions, particularly around energy production and storage. Working with Solbian, Energy Observer's technological partner since the beginning of the adventure, is an opportunity to test photovoltaic solutions in a demanding environment, and to improve them so that they can benefit all kinds of applications on land and at sea.

In this context, about once a year, the boat is put into technical shipyard to carry out not only maintenance and repairs, but also technological improvements and replacements. The aim is not only to optimize performance and reliability, but also to diversify the types of tests that can be carried out on this floating laboratory.

Photovoltaic installation development from 2017 to 2020

When first launched in 2017, Energy Observer was equipped with 95 m2 of solar panels:

- Bifacial panels specifically developed by INES (Institut National de l'Énergie Solaire) for the vessel, suspended from the stern and sides of the nacelle to capture light received directly from the sun, as well as light reflected by the water and the boat's hulls.

- Light, flexible, single-sided panels supplied by Solbian, glued to the roof of the nacelle.

As can be seen from the first aerial view below, large parts of the boat (hulls, hydrogen chests and connecting arms) had not yet been exploited.

Aerial photo of the boat at her launch in 2017

In 2018, during the first technical works since its inauguration, the solar system was extended. As can be seen in the second aerial view:

- The roof of the wheelhouse (the boat's steering position) and the lockers housing the hydrogen tanks have been covered with conformable solar panels.

- The integration of the panels on the nacelle roof was optimized to provide a larger surface area. This was made possible by anti-skid panels supplied by Solbian, which make them less slippery to walk on. It was therefore no longer necessary to leave as much space for walking between the panels.

- Finally, part of the hulls were also covered with conformable panels.

Aerial photo of the boat after the 2018 refit

During the 2019 retrofit, the photovoltaic system was modified by almost completely covering the hulls with conformable, anti-skid panels. Last but not least, in 2020, prior to her departure for the round-the-world trip, the addition of flexible panels on the link arms, as well as on the hull "caps".

Between 2017 and 2020, the photovoltaic installation was optimized and extended, from 95m2 with a power of 16.5 kWp(1) at the start of the adventure, to 202m2 with a power of 33 kWp today.

(1) kWp: kilowatt peak, i.e. the power delivered by the panels under standardized solar radiation and temperature conditions: 1000W/m2 and 25°C.

A challenging year under the tropics

From her arrival in Hawaii in May 2021 until she reached South Africa in May 2023, our laboratory vessel has been operating in the tropics and the equator, in the hottest regions of the planet. You may think this would be an optimal situation for Energy Observer and her solar-panel-based power generation, but the reality is far from it.

High temperatures don't go down well with photovoltaic panels: they instantly limit the power they can deliver. Above a certain temperature, around 25° Celsius, the electrical output power decreases as the temperature rises (example: around -0.4%/°C for Solbian SX series panels).

In the medium to long term, prolonged high panel temperatures accelerate the ageing of their encapsulation, and therefore also reduce their yield. In the tropics, panel temperatures regularly reached 75°C! Photovoltaic systems can therefore sometimes suffer yield reductions of around 20%, due solely to the high temperature of the photovoltaic panels.

In these conditions, suspended bifacial panels suffer much less from this heat, as their configuration allows them to be cooled by air passing over both sides of the panels, even at low speed, whereas panels glued to the hull cool much worse.

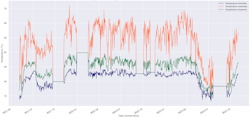

Change in solar panel temperature between May 2021 and October 2023

NB: it was noted that, in view of its integration, the temperature sensor was representative of the temperature of the bifacial photovoltaic panels, but that there was a discrepancy with the temperature of the panels glued to the hull, which cool less easily. For example, when the sensor measured 62°C, the panels bonded to the hull measured between 75°C and 80°C.

The graph above, showing temperature trends between May 2021 and July 2023, highlights two phenomena:

- Temperatures changed significantly as the boat passed through the tropics. An increase when arriving in the tropics in May 2021, and a sharp drop when leaving the tropics in May 2023.

- High temperatures, which are known to have an impact on the performance and ageing of solar panels, are maintained for two years.

But in these latitudes, it's not just a matter of heat, but also the high levels of humidity. Luca Bonci, CEO of Solbian, confirms that the combination of strong ultraviolet radiation, high heat and humidity can accelerate the ageing of solar panel coatings, which can tend to blister, allow moisture to infiltrate between the protective films, or turn yellow. These changes have an impact on the efficiency and even the integrity of the panels. On certain sections of our solar installation, we have observed a 20-30% drop in efficiency, due to a combination of aging and panel breakage. In addition to the heat, the boat has been through a number of tropical storms, with violent waves on and under the solar panels.

Illustration of moisture infiltration between solar panel films

A laboratory, yes, but tested under real conditions

In research and industry, one of the difficulties when testing new technologies is to determine how they will age over time, without having the necessary hindsight to establish this with certainty. Test methods used to try and predict the ageing of a technology involve accelerating ageing, by running it in extreme conditions. Sailing in the tropics is a great way for our laboratory vessel to test the ageing of these panels, as well as the other onboard technologies. All the observations made in this way enable us to adapt, optimize and improve the reliability of our technologies more quickly, in a shorter time span than in ordinary laboratory tests.

Since leaving France in 2020, Energy Observer's photovoltaic architecture has remained unchanged. However, system maintenance has been necessary during each of the boat's technical stops, in Singapore, Malaysia, the Seychelles and Cape Town, to replace broken or prematurely aged panels, or to refurbish them. The aim is to maintain sufficient energy efficiency to enable us to continue our next ocean crossings at a good average speed, until the end of our Odyssey.

What does happen to the panels after navigation?

Recycling solar panels is obviously a central concern, as the production of materials required for photovoltaics is not without impact on the environment. A few months ago, our energy expert Beatrice Cordiano addressed this issue in this dedicated article: Recycling solar panels: a major challenge

Besides, having a decreasing performance doesn't mean a solar panel is no longer usable. During our stopover in Singapore, we donated some of our panels to the International French School in Singapore, so that students could experiment with them in class. While the output was no longer sufficient to meet the energy needs of our catamaran, it was sufficient enough to meet the needs of the students' water fountain.

Last but not least, nothing is less impactful than extending the life of panels where possible. The smooth flexible panels supplied by Solbian, which may have yellowed under the effect of intense, prolonged sunlight (like your car's headlights), can be "polished", to remove the thin, degraded top layer and thus restore a panel that's visually as good as new. Solbian tells you more about this method in this article available on their website. This panel restoration is as much aesthetic as it is technical, since this yellowed layer absorbs part of the light and therefore reduces the solar panel's performance.

Photo of the first polish tests on Solbian photovoltaic panels: evidence of yellowing removal on the polished area

A long-standing partnership with Solbian

For the italian solar panel manufacturer Solbian, partnering with Energy Observer is an opportunity to put its innovations into practice in a challenging and real-world application. It's the biggest technological partnership to date for the Piedmont-based company.

Feedback and observations from the Energy Observer teams have enabled us to work on encapsulation techniques and materials. Luca Bonci also tells us that, for them, the specific electrical integration of their photovoltaic panels on our vessel, and the exchanges with our teams on this subject, now give them real added value in discussions with their customers about the best way to integrate their products on other projects.

This industrial and technological collaboration begins at sea and continues on land, helping to make reliable, sustainable photovoltaic solutions accessible to as many people as possible.

“Energy Observer is definitely our most important real-life trial bench. On the boat we were able to test different technologies for a long time, with continuos exposition to the most demanding weather conditions and over a large number of panels. We are really glad for the cooperation with the great EO people, we aknowledge their positive attitude that allowed us to improve the quality of Solbian solar technology. We cannot be less than enthusiastic about continuing such a great journey together.”