Electro-hydrogen hybridization - how does it work?

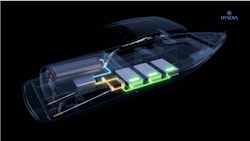

Electro-hydrogen hybridization is at the heart of the propulsion system of The New Era by HYNOVA Yachts, the first dayboat equipped with a REXH2® running on hydrogen and currently in approval phase. We spoke with Frédéric Ménière, President of EVE System, Chloé Zaied, Managing Director of HYNOVA Yachts, and Romain Jallon, Director of Operations at EODev, to explain how electro-hydrogen hybridization is ideal for decarbonized maritime mobility.

EODev: Can you detail the different components of a propulsion energy package and the differences with a similar boat that would run only on diesel or gasoline?

RJ (Romain Jallon): The Hynova's electric motors are powered by a hybrid energy source: a fuel cell (Proton Exchange Membrane Fuel Cell) on one side and batteries (LiFePO4) on the other. The hydrogen is stored in carbon fiber tanks, under pressure (350 bars). The advantages compared to the other options are the same as found on board the Energy Observer boat: zero emissions (no CO2 or fine particles), silent, and greater density of power and energy than with an "all-battery" solution.

FME (Frédéric Ménière): The fuel cell provides the average power required to propel the ship, and the batteries will provide the peaks of power. This allows for intermittent power to the propellers of 300kW with a fuel cell of 60kW. The overall efficiency is improved because the battery thus operates at its optimum operating point, with 60% efficiency. In diesel engines, the overall efficiency is around 30%, with double heat loss. In addition, the Diesel must be sized for maximum peak power. The hydrogen hybrid solution makes it possible, like a PHEV (Plugin Hybrid Electric Vehicle), to perform short services 100% electric on battery, and long services with the energy supply of hydrogen.

CZ (Chloé Zaied): This boat will sail without noise, without vibrations, without pollution of water or air. We might even find the propellers noisy. It will be a surprising experience.

EODev: How does hydrogen-battery hybridization work and why this sizing, a fuel cell with three batteries?

RJ: The fuel cell and the batteries are connected in parallel to the voltage network supplying the motors. The Fuel Cell can only supply power, while the battery can supply power to motors or receive power from the Fuel Cell. The role of the batteries is to respond to calls for power from the motors, and to provide additional power to achieve maximum speed. The relatively short spikes in speed are provided by the two sources together. Sizing the fuel cell to maximum power would reduce the compactness of the propulsion chain. A hybridization management algorithm has been developed to optimize the operation of the whole set.

FME: The battery is sized with respect to the average power required for the operation of the vessel. On HYNOVA, we are on 80kW. The batteries are sized according to the maximum intermittent power or in energy according to the desired battery life. Of course the weight, size and price constitute a limit which can lead to reconsidering the power / energy requirements. On The New Era, we are on 250kW in battery power and 132kWh in energy. But all configurations are possible depending on the use profile.

EODev: Can we therefore say that, if we compare with a "classic" hybrid solution which includes combustion engine, generator and batteries, that hydrogen replaces diesel, and the Fuel Cell replaces the combustion engine?

RJ: Almost. Diesel is the source of energy, the combustion engine transforms the chemical energy of diesel into mechanical energy. Hydrogen is the source of energy, the Fuel Cell transforms the chemical energy of hydrogen into electrical energy, the electric motor transforms electrical energy into mechanical energy. So I would say that the Diesel is replaced by hydrogen and the Fuel Cell, and the combustion engine is replaced by an electric motor.

FME: In addition, it should be noted that hydrogen is not a source of fossil energy like Diesel, but an energy vector. Let's say that from the point of view of the user of the boat, hydrogen replaces diesel, but from a macroeconomic point of view, it is the whole "electricity network + hydrogen" which replaces Diesel.

EODev: What battery technology is used on board the HYNOVAs, and what difference(s) do they have with other batteries (for cars for example)?

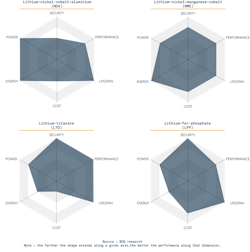

RJ: The batteries designed by EVE System use Lithium-Iron-Phosphate technology. Less dense than Lithium NMC technology used in cars but much more immune to thermal runaways leading to battery fires that cannot be extinguished. In the discussions we have with Bureau Veritas on the certification of a hydrogen vessel, they advise us against the use of NMC batteries which they do not certify at the moment.

FME: The different lithium battery families are listed below. It's all about compromise. The automobile uses NCA (Tesla) and NMC (all others). In heavy industries, and especially in boats, LTO and LFP are used for their safety. LFP is more energetic than LTO. The LTO is made for heavy usage, fast charging, but limited use - it's expensive and heavy. On HYNOVA, we use LFP, as on the main electric or hybrid work boats that sail in France. It is a good solution to combine safety, performance and durability.

EODev: Can you explain the "marinization" of the components (batteries and FCs) and why is it important?

RJ: "Marinization" consists in providing the equipment with protection to adapt to the marine environment. Exposure to salt air, spray, leads to early corrosion of metal parts, electrical wires and connectors. It is therefore a matter of favoring 316L stainless steel equipment, of ensuring the compatibility of materials to avoid electrolytic couples, of applying varnish on the metal parts, a silicone paste on the unprotected electrical connectors, of dimensioning and developing tailor-made air filters to protect against sulfur-like particles that can be found in the air at sea, and to optimize weight and dimensions for easy integration. It is also about managing safety around the use of hydrogen on a ship whose conditions of use at sea are more restrictive than on a land vehicle. It is thus a question of redundancy of the safety systems, and of the capacity of the vessel to be able to reach a coastal shelter even in the event of the failure of a particular component of the propulsion system. It's quite similar to the principles applied in airplanes, for the same reasons. If there is a problem, you can't just leave your vehicle on the side of the road and continue on foot.

FME: The work boat market requires, depending on their size, to comply with the rules for marine certification of installations. This involves “type approvals” on the components, and more or less extensive design reviews by the certification bodies. This "type certification" concerns all the safety components of the vessel, such as motors, shafts, propellers, reducers, variators, batteries, gas controls, circuit breakers, cables, etc. It’s almost endless! Regarding the fuel cell, it may not appear in the list of safety components if the batteries are large enough and redundant. Marine battery certification consists of responding to specific environmental tests (vibration, damp heat, dry heat), functional tests, standard performance tests (IEC 62619 and IEC62620). Compared to conventional industrial standards, the level of vibration resistance is higher, and the damp heat test is drastic. In HYNOVA yachts the tanks are outside the structure, although the designers have done a fine job of making it look like there are no cylinders on the boat. This ensures that the hydrogen will not be confined in the event of a leak. The Fuel Cell is in its own compartment. it is also not possible to switch on any equipment before the hydrogen safety controller has verified the absence of hydrogen. In the event of a fire, vent lines allow the rapid evacuation of the hydrogen from the tanks: in 30 seconds the hydrogen is evacuated, making the boat much safer than a diesel boat whose fuel cannot be evacuated.

EODev: The problem of the "recyclability" of batteries and the use of rare and / or expensive materials whose extraction is an environmental concern: what are your points of view on the question?

FME: Not that rare, not that polluting either, especially for LFP chemistry. Lithium, iron phosphate, aluminum, copper. No Nickel, No Cobalt, No Manganese, No Lead, No Cadmium, No Heavy Metals, No Glues, No Cooling Fluid, No Resins… In addition, the recycling channel is being put in place. Today, it exists at pre-industrial levels, but the cost of recycling is already very low (€1/kg) and will continue to decline with increasing volumes. HYNOVA batteries can be completely dismantled, and their recycling enables the components to be sorted upstream to either reuse them or reduce the cost of treatment.

CZ: HYNOVA is well aware of the carbon footprint of a LiFePo battery. Thanks to the integration of foils, an energy saving of 25% will be possible while maintaining the performance of the boat ; and this allows us not to use an additional battery representing 2,922 kg of CO2 in the Life Cycle Analysis.

To go further:

The Green Hydrogen Revolution Is Now Underway - Forbes

What is hydrogen? - Climate Ch2ampion

First wave of ships explore green hydrogen as route to net zero - Reuters

Toyota Brings The Hydrogen Fuel Cell To The Marine Industry - Clean Technica